Freight risk management faces challenges like shipment delays, damage to goods, unexpected costs & rate volatility, regulatory compliance issues, supply chain disruptions, insufficient documentation & paperwork, lack of supply chain visibility.

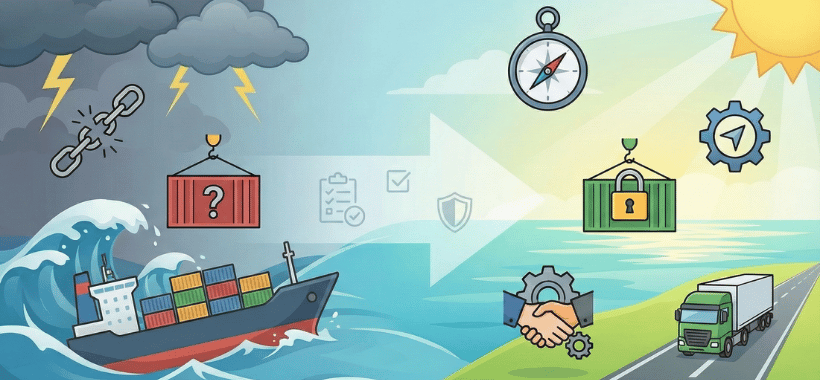

If you’ve been in the freight or trucking business for even a short time, you know one thing for sure: risk is everywhere. Shipments get delayed, paperwork goes missing, and costs pop up that no one budgeted for. Whether you’re a shipper, a broker, or a small trucking company, these challenges can cut into profits, damage customer relationships, and create endless stress.

The good news? While you can’t remove risk completely, you can manage it smartly. With the right strategies and partners, risks become manageable even opportunities to improve your business.

Let’s break down seven of the most common freight risks you’ll face and the practical solutions that can help you stay ahead.

1. Shipment Delays

The Problem: Delays happen for all kinds of reasons: traffic jams, driver shortages, breakdowns, weather events, or even miscommunication at loading docks. Every delay costs money, frustrates customers, and can trigger penalties.

The Solution: Use predictive route planning tools that factor in traffic and weather. Build a small buffer window into delivery schedules.

Encourage real-time communication — if a delay is unavoidable, update the customer immediately instead of letting them chase you down.

Pro Tip: Some small fleets avoid penalties by setting up automated notifications that alert customers the moment a delay is detected.

2. Damage to Goods

The Problem: Few things sour a client relationship faster than freight arriving broken or spoiled. Common causes include improper loading, bad weather, or even equipment failure.

The Solution: Train drivers and loaders on proper securement practices. Use load securement technology like straps, dunnage bags, or sensors. Always keep an inspection checklist before pulling out.

Document freight with photos at pickup — it protects you from claims you don’t deserve.

Pro Tip: Encourage shippers to invest in proper packaging. Even the best loading practices can’t fix weak pallets or flimsy boxes.

3. Unexpected Costs & Rate Volatility

The Problem: Fuel surcharges, detention time, accessorial fees, and fluctuating spot market rates can destroy profitability. Small trucking companies often feel this pinch the hardest.

The Solution: Lock in contract rates with repeat shippers where possible. Negotiate accessorials upfront to avoid surprises. Track costs using simple TMS software or spreadsheets so you know exactly where profits are being eaten up. Consider a fuel card program to save on diesel.

Pro Tip: Brokers can protect margins by keeping a rolling average of costs and using that data to set customer expectations.

4. Regulatory Compliance Issues

The Problem: DOT rules, FMCSA audits, Hours-of-Service limits, and ELD requirements are not just “big company” problems — they affect every carrier on the road. Non-compliance leads to fines, out-of-service orders, or worse: lost contracts.

The Solution: Invest in a compliance service provider that helps with record-keeping, log audits, and safety checks. Schedule quarterly compliance reviews instead of scrambling before an audit. Train drivers regularly — rules change, and ignorance isn’t an excuse.

Pro Tip: Even one compliance slip-up can show up on your CSA score. Customers often check these scores before awarding freight.

5. Supply Chain Disruptions

The Problem: From hurricanes to port congestion, supply chains face disruptions that no one can control. A single weak link — a delayed container, a strike, or a shortage — can ripple down and shut operations for days.

The Solution: Build redundancy into your supply chain (multiple carriers, backup suppliers). Stay flexible with routing options and mode shifts (truck, rail, air). Communicate with customers about contingency plans ahead of time so they’re not blindsided.

Pro Tip: Shippers who diversify their carrier base recover faster when disruptions hit. Relying on one provider is risky.

6. Insufficient Documentation & Paperwork

The Problem: Missing bills of lading, inaccurate proof of delivery (PODs), or lost rate confirmations cause payment delays and disputes. For small trucking companies, cash flow is critical — even one missing document can throw finances off track.

The Solution: Use digital document storage or scanning apps so nothing gets lost. Standardize with checklists to confirm all paperwork before leaving a dock. Automate documentation wherever possible — many TMS platforms now include this feature.

Pro Tip: Don’t hand off paperwork without scanning or photographing it first. That “backup copy” has saved many small carriers from lost revenue.

7. Lack of Supply Chain Visibility

The Problem: Shippers and brokers want to know where their freight is now. Without visibility, trust breaks down, and customers may switch to providers who can deliver real-time updates.

The Solution: Use GPS tracking apps or ELD-based solutions that share live locations. Implement TMS software that integrates with carriers. Even small fleets can offer visibility with affordable tools like Trucker Tools, MacroPoint, or FourKites.

Pro Tip: Visibility isn’t just about tracking — it’s about communication. A quick text or email confirming status can mean the difference between a happy customer and a frustrated one.

FAQs

What are common freight risk management problems?

Delays, damaged goods, compliance failures, unexpected costs, and poor visibility are the most frequent headaches for shippers, brokers, and carriers.

How do documentation errors create freight risks?

They cause delayed payments, disputes, and even legal problems. Something as simple as a missing signature can stall cash flow for weeks.

How can better communication reduce freight risks?

Transparency builds trust. Real-time updates let shippers and brokers adjust plans before a problem becomes a crisis.

Why is cargo insurance important in freight risk management?

Because no matter how careful you are, accidents happen. Cargo insurance protects carriers financially and gives shippers peace of mind.

What are the best solutions for managing freight risks?

Use a mix of technology, compliance support, clear communication, and strong partnerships. No single fix works — it’s about layering protections.

Conclusion

Freight risk management isn’t about eliminating problems — it’s about being prepared. From delays to compliance, risks will always exist. The difference between companies that struggle and those that thrive is how they respond.

At MPact Logistics, we specialize in helping shippers, brokers, and small trucking companies reduce risks through compliance-driven, practical solutions. Whether it’s staying audit-ready, improving visibility, or streamlining documentation, we’ve got you covered.

Ready to protect your business from freight risks? Contact MPact Logistics today and let’s build a smarter, safer supply chain together.

Related Info: 7 Freight Risk Management Checklist | Reduce Losses in Your Supply Chain

Related Info: Why Freight Risk Management Matters for a Profitable Supply Chain